Our client is a global leader in alumina production, supplying approximately 8% of the world market. The efficiency of the refining process is critically dependent upon analysis of the continuously circulating refining liquor. The company needed to replace an aging, manually intensive in-house analyser with a modern, automated solution capable of accelerating throughput, reducing operating costs, and operating in a 24/7 environment with minimal human intervention.

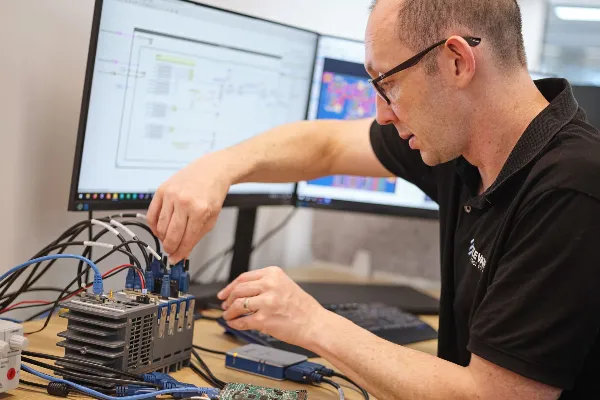

The company engaged Elevate Controls to develop a next-generation multi-analysis titration system—one that could achieve four times the sample throughput of its predecessor, at half the scale-up cost, while maintaining laboratory-grade accuracy and reliability.