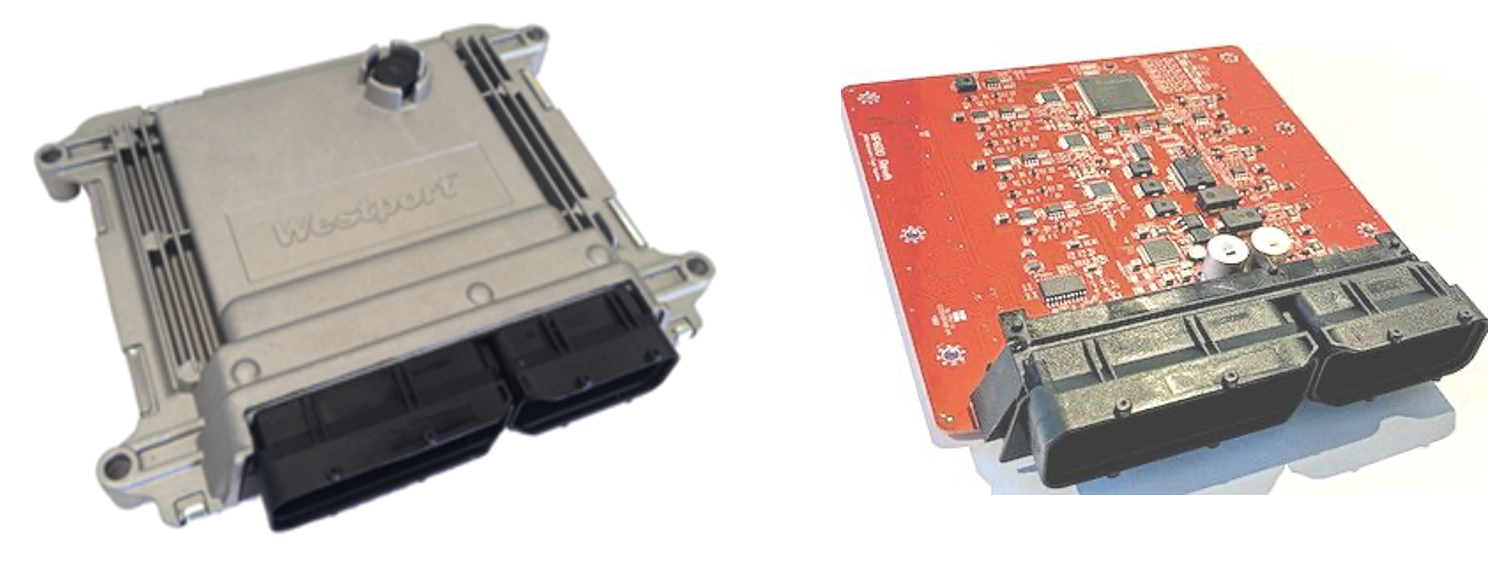

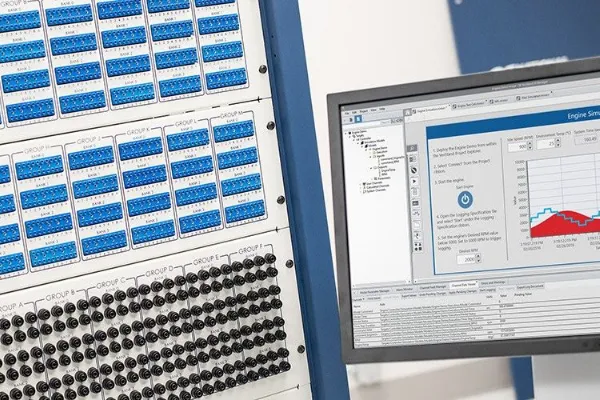

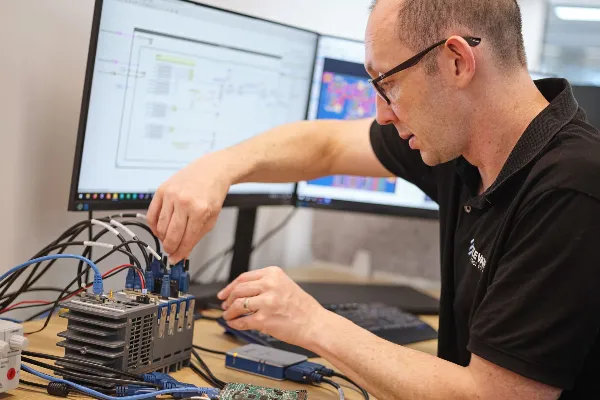

Elevate Controls was contracted to design and implement a comprehensive End-Of-Line (EOL) Test System that automated all quality assurance, compliance and traceability procedures for a Gas Engine Control Unit (ECU) for medium duty commercial vehicles.

The EOL Test system was deployed to an offshore manufacturing facility in India.