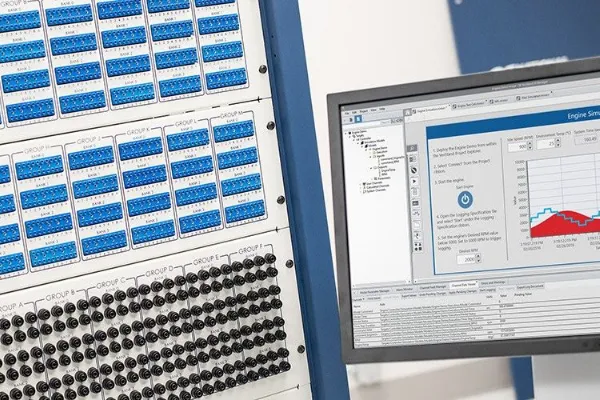

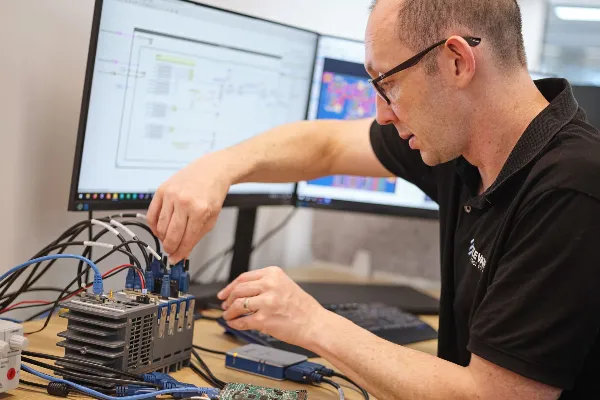

Elevate Controls was engaged to design and deliver a robust Field Test System to support in-service maintenance and fault diagnostics of Gas Engine Control Units (ECUs) for medium-duty commercial vehicles.

This project extended our long-standing partnership with the ECU manufacturer, which began over a decade ago when we developed their original End-Of-Line (EOL) Test System. Over time, the manufacturer discovered that ECUs returned under warranty were often fully functional or failed due to external factors not covered by warranty. This increased warranty support costs and reduced production capacity, as returned units competed for access to the in-factory EOL Test system.