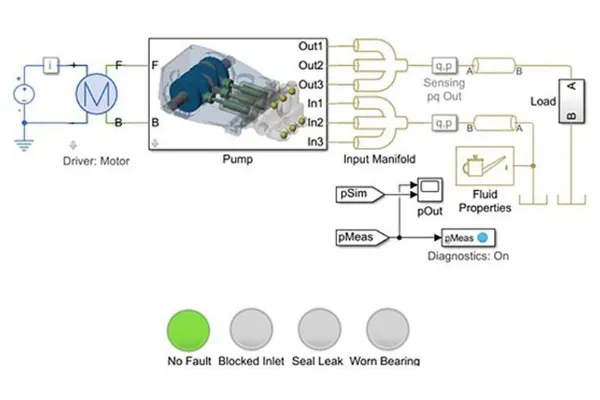

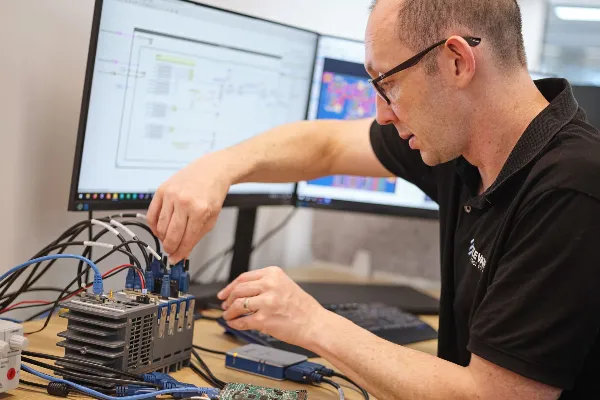

Our client is a leader in sustainable energy solutions and required a stable Hardware-in-the-Loop (HIL) testing system to support developing and validating a new Vehicle Control Unit (VCU). As the VCU plays a critical role in managing vehicle subsystems, it needed a test platform to simulate varying operational and fault scenarios before real-world deployment.

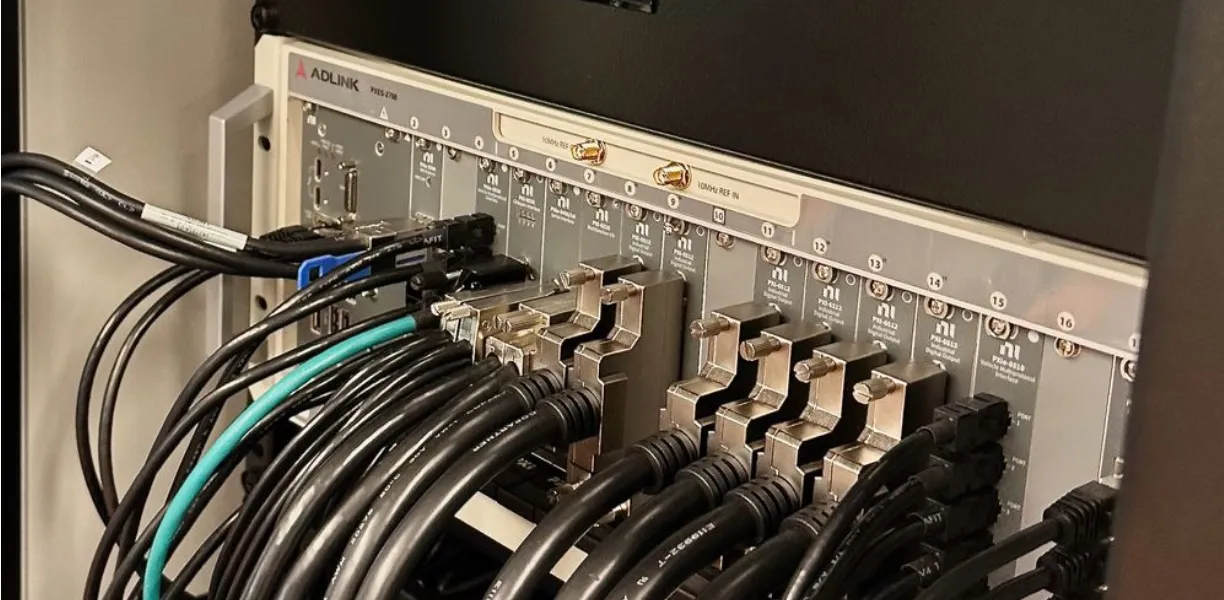

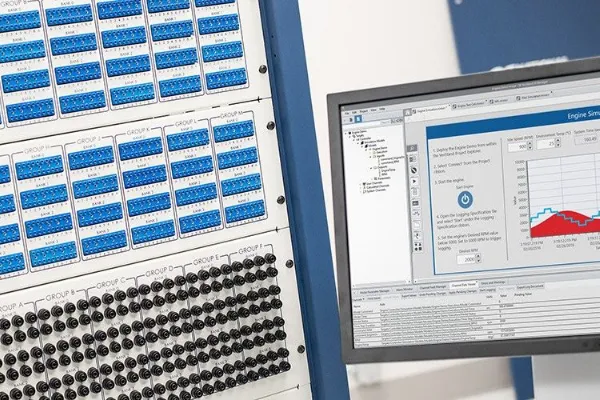

The challenge was to deliver a scalable, flexible, and powerful HIL environment allowing engineers to assess system performance, resilience, and reliability under controlled lab conditions. Elevate Controls was engaged to design, develop, and deploy four turnkey HIL systems to meet this need.