Rail hunting is a lateral oscillation phenomenon where train wheels alternately make and break contact with the inner track edges. Excessive rail hunting increases the risk of track wear, damage, and derailment. Factors including speed, track conditions, and wheel/track interaction play a significant role in determining hunting severity and, in turn, maximum allowable travel speeds.

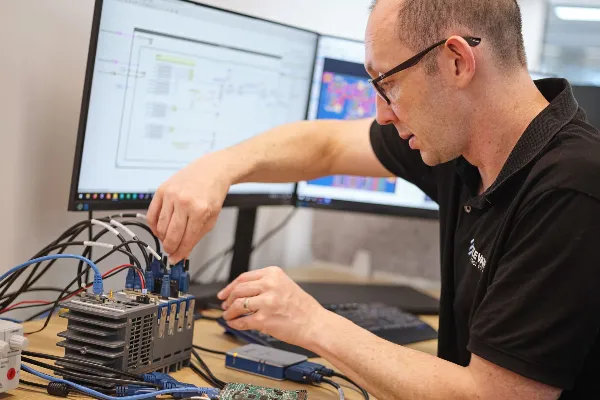

Following a derailment on a critical rail corridor, a national network operator required a reliable, high-precision system to investigate whether rail hunting contributed to the incident. They turned to Elevate Controls to design a portable, autonomous, high-speed rail hunting detection system capable of long-term deployment in a remote, harsh environment.